- Dew Point Meters

- Gas Analysers

- Portable Gas Detector

- Moisture And Dew Point Analyzer

- Dust Monitor

- Gas Monitoring Systems

- Gas Leak Detectors

- Gas Transmitters

- VOC Leak Detector

- Air Quality Monitoring System

- Online Continuous Emission Monitoring System-OCEMS

- Dew Point Monitors

- Gas Detector

- Opacity Monitor

- Portable Flue Gas Analyzer

- Online SOX & NOX Gas Analyzer

- Methane Gas Leak Detector

- Hydrogen Purity Analyzer

- Gas Purity Analyzer

- Effluent Monitoring Systems

- Producer Gas Analyzer

- Gas Detector Calibration Service

- Portable Gas Monitors

- Gas Sensor Transmitter

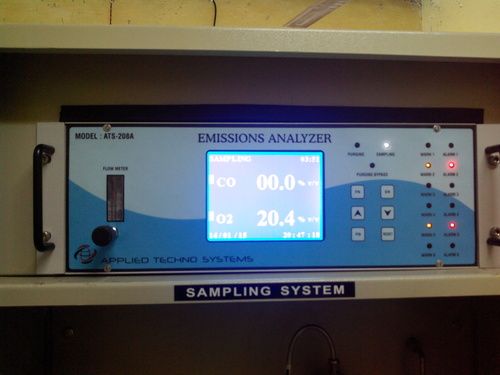

Fixed Gas Monitoring system

Product Details:

Fixed Gas Monitoring system Price And Quantity

- 50000 INR/Unit

- 15000.00 - 150000.00 INR/Unit

- 1 Unit

Fixed Gas Monitoring system Trade Information

- Cash Advance (CA) Cash in Advance (CID)

- 100 Unit Per Week

- 3 Days

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa

- All India South India Central India West India North India East India Gujarat Karnataka Kerala Lakshadweep Mizoram Meghalaya Manipur Andhra Pradesh Bihar Chandigarh Daman and Diu Goa Jharkhand Odisha Punjab Assam Delhi Dadra and Nagar Haveli Andaman and Nicobar Islands Arunachal Pradesh Chhattisgarh Haryana Himachal Pradesh Jammu and Kashmir Madhya Pradesh Maharashtra Nagaland Rajasthan Sikkim Tamil Nadu Telangana Tripura Pondicherry Uttar Pradesh Uttarakhand West Bengal

Product Description

A Fixed Gas Monitoring System is a permanently installed gas detection system used in industrial and commercial environments to continuously monitor the presence of hazardous gases. These systems are designed to protect facilities, equipment, and personnel by providing real-time detection and alerts when dangerous gas concentrations (e.g., toxic, flammable, or asphyxiant gases) are detected.

Fixed gas monitors are typically placed at strategic locations where gas leaks or accumulation are likely, such as in processing plants, refineries, power generation facilities, and storage areas. They provide 24/7 monitoring and are integrated with control systems to trigger alarms, ventilation, or even shut down processes automatically in case of dangerous gas levels.

Key Features:

- Continuous Monitoring: Fixed systems provide real-time, around-the-clock gas detection.

- Multi-point Detection: Can monitor multiple gas types and points across large areas.

- Integration with Safety Systems: Often integrated with control panels and automated safety systems to trigger responses like alarms or ventilation activation.

- Sensor Technology: Various sensors, such as infrared, electrochemical, catalytic bead, or photoionization detectors, depending on the gas type.

- Data Logging: Continuous recording of gas levels for compliance, analysis, and maintenance purposes.

- Customizable Alerts: Visual, audible alarms, and remote notifications when gas concentrations reach unsafe levels.

Typical Applications:

- Oil & Gas Refineries

- Chemical Plants

- Power Plants

- Manufacturing Industries

- Wastewater Treatment Plants

- Pharmaceutical and Research Labs

FAQs about Fixed Gas Monitoring Systems:

-

What is the purpose of a fixed gas monitoring system?

- A fixed gas monitoring system is installed to detect hazardous gases in real-time, ensuring the safety of personnel and the facility by preventing accidents due to gas leaks or buildup.

-

What types of gases can a fixed gas monitoring system detect?

- These systems can detect a wide range of gases, including toxic gases like hydrogen sulfide (H2S) and carbon monoxide (CO), combustible gases like methane (CH4), and oxygen (O2) deficiency or enrichment.

-

How does a fixed gas monitor differ from a portable gas detector?

- A fixed gas monitor is permanently installed and provides continuous monitoring in a fixed location, while a portable gas detector is a handheld device used for temporary or personal gas monitoring.

-

How are fixed gas monitors powered?

- Most fixed gas monitors are powered by the facilitys electrical systems, though backup batteries or other power sources are available to ensure uninterrupted operation during power outages.

-

Can fixed gas monitoring systems be integrated with alarm systems?

- Yes, they are commonly integrated with alarm systems, both visual and audible, and may also be connected to emergency shutdown or ventilation systems.

-

How often should fixed gas monitors be calibrated?

- Calibration frequency depends on the sensor type and manufacturer recommendations, but calibration typically occurs every 6 to 12 months to ensure accuracy.

-

What is the lifespan of the sensors in fixed gas monitoring systems?

- Sensor lifespan varies by type, but most electrochemical sensors last 2-3 years, while infrared sensors may last longer. Regular maintenance is required to ensure optimal performance.

-

Are fixed gas monitors suitable for hazardous environments?

- Yes, many fixed gas monitors are specifically designed for hazardous environments and come with explosion-proof housings to ensure safety in areas with combustible gases.

-

What industries benefit from fixed gas monitoring systems?

- Industries such as oil and gas, chemical processing, power generation, manufacturing, and laboratories rely on these systems to ensure safety by detecting dangerous gas levels.

-

How are fixed gas monitoring systems maintained?

- Regular sensor calibration, testing, and maintenance checks are necessary to ensure system accuracy and performance. Many systems come with self-diagnostic features to monitor sensor health and alert users to any issues

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese