- Dew Point Meters

- Gas Analysers

- Portable Gas Detector

- Moisture And Dew Point Analyzer

- Dust Monitor

- Gas Monitoring Systems

- Gas Leak Detectors

- Gas Transmitters

- VOC Leak Detector

- Air Quality Monitoring System

- Online Continuous Emission Monitoring System-OCEMS

- Dew Point Monitors

- Gas Detector

- Opacity Monitor

- Portable Flue Gas Analyzer

- Online SOX & NOX Gas Analyzer

- Methane Gas Leak Detector

- Hydrogen Purity Analyzer

- Gas Purity Analyzer

- Effluent Monitoring Systems

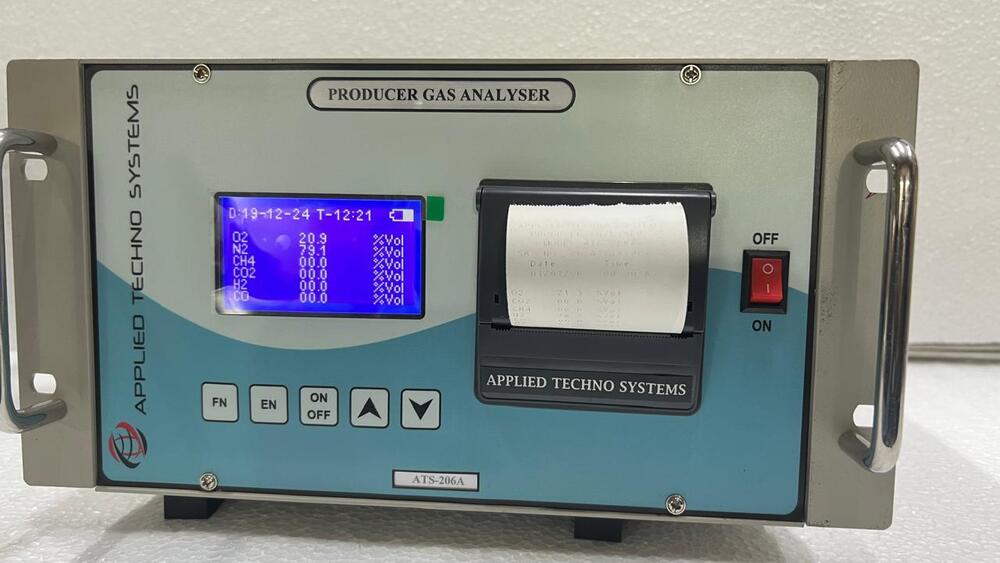

- Producer Gas Analyzer

- Gas Detector Calibration Service

- Portable Gas Monitors

- Gas Sensor Transmitter

Gas composition monitoring

750000 INR/Unit

Product Details:

- Dimension (L*W*H) 500 x 300 x 200 Millimeter (mm)

- Voltage 240 Volt (v)

- Color Grey

- Humidity 85%RH

- Material Aluminium

- Power Supply Electric

- Temperature 0 - 55 Celsius (oC)

- Click to View more

X

Gas composition monitoring Price And Quantity

- 1 Unit

- 750000 INR/Unit

Gas composition monitoring Product Specifications

- 500 x 300 x 200 Millimeter (mm)

- Grey

- 240 Volt (v)

- 85%RH

- Aluminium

- 0 - 55 Celsius (oC)

- Electric

- Industrial

Product Description

General Overview

Purpose: To measure the composition of producer gas from gasifiers and combustion processes for quality control, optimization, and safety monitoring.

2. Measurement Specifications

- Measured Components:

- Carbon Monoxide (CO): 050% by volume

- Carbon Dioxide (CO): 050% by volume

- Hydrogen (H): 050% by volume

- Methane (CH): 010% by volume

- Oxygen (O): 025% by volume

- Nitrogen (N): Balance (calculated or measured)

- Moisture (HO): Optional, 010%

- Tar Content: Optional (qualitative or quantitative assessment)

- Detection Limit: Down to 0.1% for major components, ppm-level detection for trace gases.

- Accuracy: 1% of full scale for critical components.

- Response Time: <10 seconds for 90% response.

3. Operating Conditions

- Gas Temperature: 0800C (with appropriate sampling system).

- Gas Pressure: 0.12.0 bar.

- Ambient Conditions:

- Operating Temperature: 050C.

- Relative Humidity: 85% (non-condensing).

4. Analyzer Technology

- Measurement Principles:

- Non-dispersive infrared (NDIR) for CO, CO, and CH.

- Thermal conductivity detector (TCD) for H.

- Electrochemical or zirconia sensors for O.

- Optional tar measurement via gravimetric or online methods.

- Multi-Gas Analysis: Simultaneous measurement of key components.

- Sampling System: Heated probe and lines to prevent condensation.

5. Calibration and Maintenance

- Calibration Gas Requirements: Certified multi-component gas mixtures.

- Auto-Calibration: Optional feature for automatic zero and span checks.

- Maintenance Interval: Monthly sensor checks; annual full calibration recommended.

- Sensor Lifetime: 35 years (typical).

6. Communication and Interface

- Display: Touchscreen LCD with real-time composition readout.

- Data Logging: Internal storage with USB or SD card support.

- Outputs:

- Analog: 420 mA, 010V.

- Digital: RS485, Modbus RTU, Ethernet.

- IoT-Ready: Optional Wi-Fi or GSM connectivity for remote monitoring.

7. Physical and Power Specifications

- Dimensions: Compact design, e.g., 500 x 300 x 200 mm.

- Weight: 15 kg.

- Power Supply: 100240V AC, 50/60 Hz or 24V DC.

- Mounting Options: Rack-mounted, wall-mounted, or portable configurations.

8. Safety Features

- Explosion-Proof Design: Certified for use in hazardous areas (ATEX, IECEx).

- Over-Temperature Protection: Prevents overheating in the sampling system.

- Intrinsically Safe Components: Optional for flammable environments.

9. Applications

- Industries: Biomass and coal gasification, chemical processing, steel production.

- Processes: Gasifier output monitoring, combustion optimization, energy efficiency.

- Additional Uses: Environmental monitoring, safety compliance.

10. Standards and Compliance

- ISO Standards: Compliant with ISO 19739 for syngas analysis.

- Other Standards: ASTM D7651 for fuel gas testing, ATEX/IECEx for hazardous environments.

This specification provides a foundation for selecting or designing a producer gas analyzer. Let me know if you need customization for a specific industry or operational requirements

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese