- ओस बिंदु मीटर

- गैस विश्लेषक

- पोर्टेबल गैस डिटेक्टर

- नमी और ओस बिंदु विश्लेषक

- धूल मॉनिटर

- गैस निगरानी प्रणाली

- गैस रिसाव डिटेक्टर

- गैस ट्रांसमीटर

- वीओसी लीक डिटेक्टर

- वायु गुणवत्ता निगरानी प्रणाली

- ऑनलाइन सतत उत्सर्जन निगरानी प्रणाली-ओसीईएमएस

- ओस प्वाइंट मॉनिटर्स

- गैस डिटेक्टर

- अपारदर्शिता मॉनिटर

- पोर्टेबल फ़्लू गैस विश्लेषक

- ऑनलाइन एसओएक्स और एनओएक्स गैस विश्लेषक

- मीथेन गैस रिसाव डिटेक्टर

- हाइड्रोजन शुद्धता विश्लेषक

- गैस शुद्धता विश्लेषक

- प्रवाह निगरानी प्रणाली

- निर्माता गैस विश्लेषक

- गैस डिटेक्टर अंशांकन सेवा

- पोर्टेबल गैस मॉनिटर्स

- गैस सेंसर ट्रांसमीटर

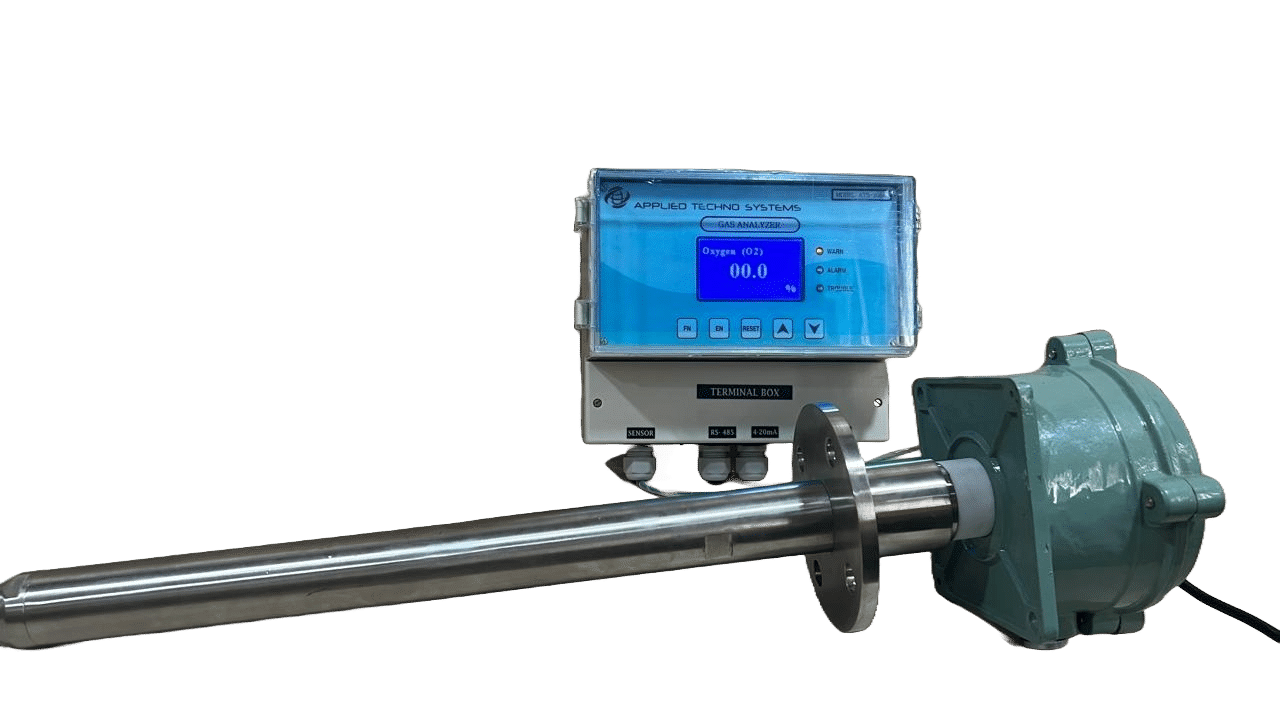

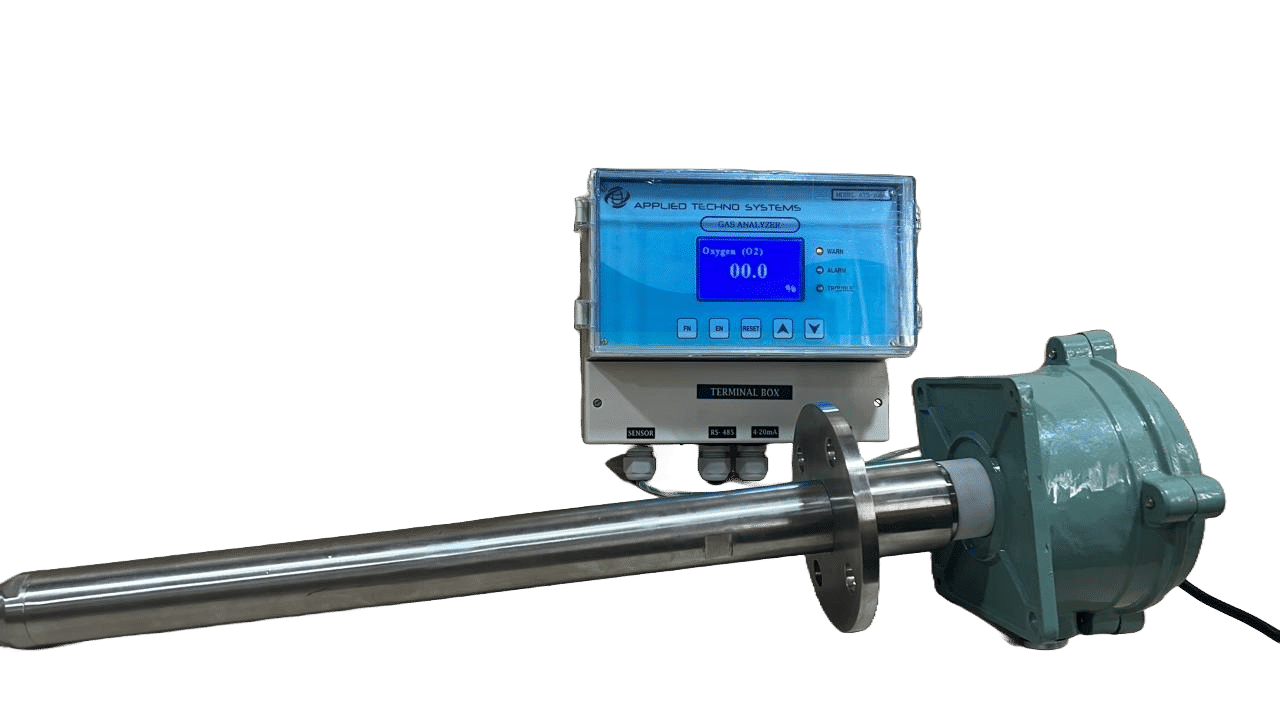

Zirconia oxygen sensor

उत्पाद विवरण:

मूल्य और मात्रा

- 1

उत्पाद वर्णन

-

Zirconia Sensor Element: The core component is a zirconium dioxide (zirconia) ceramic, typically doped with yttria, that functions as a solid electrolyte. When exposed to high temperatures, zirconia allows oxygen ions to move through its lattice structure, generating a voltage that corresponds to the oxygen concentration.

-

High Temperature Tolerance: These analyzers work effectively at high temperatures, often above 600C (1112F), making them suitable for environments like flue gas, combustion chambers, and kilns.

-

In-Situ Installation: As an in-situ device, it measures directly within the gas flow. This design eliminates the need for sample extraction and conditioning, making it quicker to respond to changes in oxygen levels.

-

Electrochemical Principle: Zirconia-based analyzers leverage the Nernst equation, which relates the EMF (voltage) generated across the zirconia electrolyte to the partial pressure of oxygen in the measured gas.

-

Fast Response Time: Due to the direct measurement approach and high-temperature functionality, these analyzers offer a fast response time, critical for controlling combustion processes efficiently.

Applications

- Combustion Control: Used in power plants, cement kilns, steel manufacturing, and petrochemical industries to optimize combustion, reduce emissions, and improve fuel efficiency.

- Process Safety: Monitoring oxygen levels to prevent explosive mixtures or ensure safe operating conditions.

- Environmental Compliance: Helps in maintaining low oxygen levels to control NOx and CO emissions.

Benefits

- Real-Time Measurement: Instantaneous data helps optimize processes.

- Low Maintenance: Limited or no need for gas sampling lines, reducing downtime.

- Durability: Designed for continuous operation in challenging industrial environments.

In-situ zirconia-based oxygen analyzers provide essential control and monitoring capabilities in various high-temperature industrial processes, ensuring both efficiency and safety.

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese