- Dew Point Meters

- Gas Analysers

- Portable Gas Detector

- Moisture And Dew Point Analyzer

- Dust Monitor

- Gas Monitoring Systems

- Gas Leak Detectors

- Gas Transmitters

- VOC Leak Detector

- Air Quality Monitoring System

- Online Continuous Emission Monitoring System-OCEMS

- Dew Point Monitors

- Gas Detector

- Opacity Monitor

- Portable Flue Gas Analyzer

- Online SOX & NOX Gas Analyzer

- Methane Gas Leak Detector

- Hydrogen Purity Analyzer

- Gas Purity Analyzer

- Effluent Monitoring Systems

- Producer Gas Analyzer

- Gas Detector Calibration Service

- Portable Gas Monitors

- Gas Sensor Transmitter

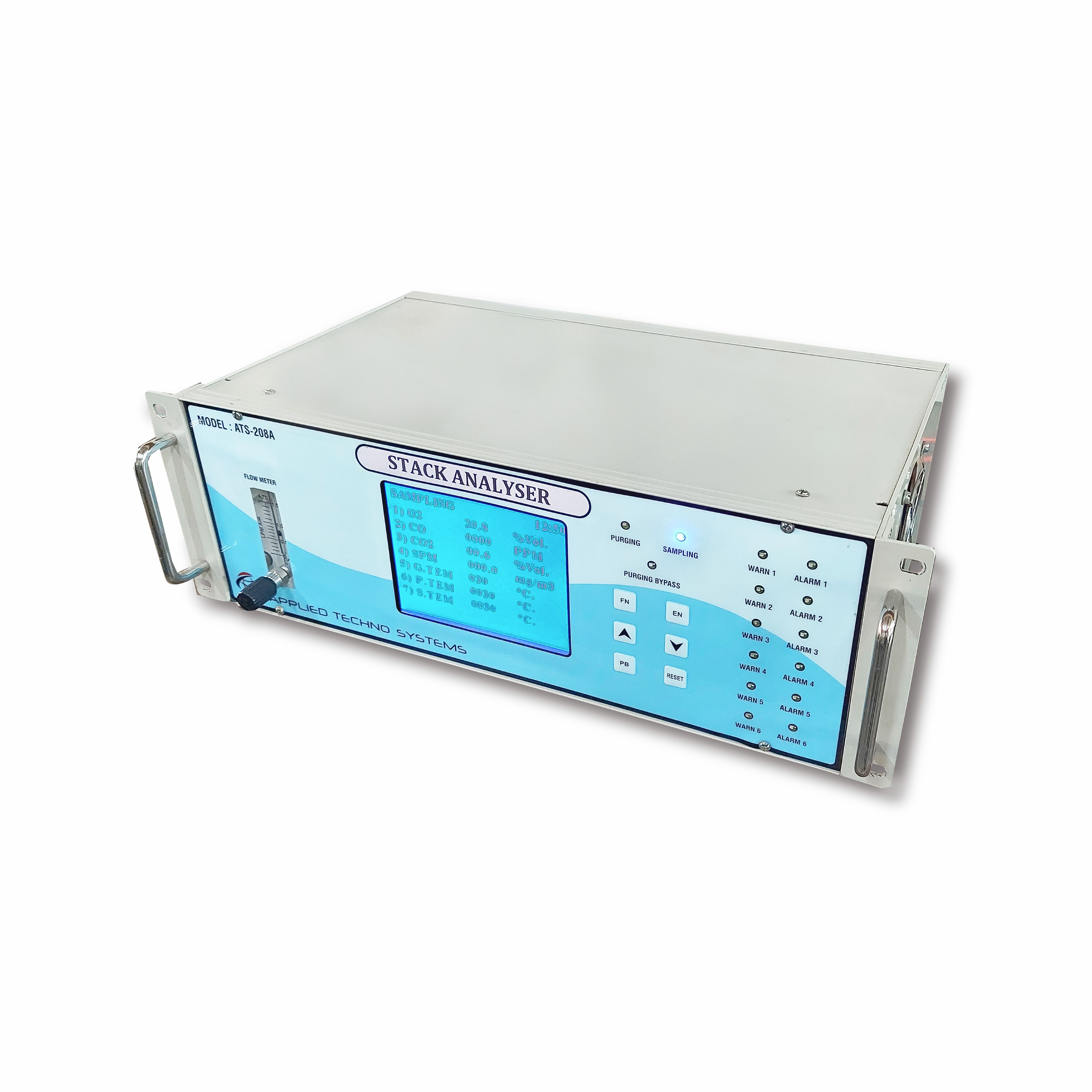

SOx, NOx, and CO monitoring

725000 INR/Number

Product Details:

X

SOx, NOx, and CO monitoring Price And Quantity

- 1 Number

- 725000 INR/Number

- 950000.00 - 1.00 INR/Number

Product Description

Measurement Ranges

- SOx (SO): Typical measurement ranges are from 0“200 ppm to 0“5,000 ppm, depending on regulatory requirements and process conditions.

- NOx (NO, NO): Measurement ranges often vary from 0“100 ppm to 0“1,000 ppm, adjustable based on the expected concentration in the exhaust.

- CO: CO is often measured in percentage values, typically 0“20%, although some applications may require lower or higher ranges (e.g., 0“50%).

2. Detection Methods

- SOx: Commonly measured using UV fluorescence, non-dispersive infrared (NDIR), or electrochemical sensors.

- NOx: NOx levels are measured using chemiluminescence, NDIR, or electrochemical detection.

- CO: Primarily monitored using NDIR sensors or infrared gas analyzers.

3. Response Time

- SOx and NOx: Generally, response times range from 30 seconds to 2 minutes for real-time monitoring.

- CO: Typically has response times around 15 to 30 seconds.

4. Accuracy and Precision

- SOx: Typically ±1% of full scale.

- NOx: Around ±2% of full scale.

- CO: ±1% of the measurement range.

5. Resolution

- SOx: Typically around 1 ppm.

- NOx: 0.1“1 ppm, depending on sensor sensitivity.

- CO: Typically 0.01% for higher precision.

6. Operating Temperature

- Generally from -20C to +50C for standard stack monitoring systems, but some applications may require operation in higher temperature ranges (up to 300C with cooling or sample conditioning).

7. Sample Conditioning System

- Includes filters, condensers, and pumps to prepare samples at high temperatures and humidity, especially in combustion environments.

8. Data Output and Communication

- Output Signals: 4“20 mA, RS-485, Modbus, Ethernet for integration with SCADA or other data acquisition systems.

- Data Logging: Systems should have onboard memory and support for data logging, as well as remote data access options.

9. Compliance Standards

- Should meet standards such as U.S. EPA 40 CFR Part 60, European EN 14181, and local environmental regulations for emissions.

10. Calibration Requirements

- Automated or manual calibration with span and zero gases (e.g., nitrogen for zeroing, standard reference gases for span calibration). Calibration intervals depend on regulation and analyzer type.

These specifications ensure that SOx, NOx, and CO monitoring systems meet the accuracy, reliability, and regulatory compliance required for effective emissions monitoring in industrial applications

Enter Buying Requirement Details

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese