- ओस बिंदु मीटर

- गैस विश्लेषक

- पोर्टेबल गैस डिटेक्टर

- नमी और ओस बिंदु विश्लेषक

- धूल मॉनिटर

- गैस निगरानी प्रणाली

- गैस रिसाव डिटेक्टर

- गैस ट्रांसमीटर

- वीओसी लीक डिटेक्टर

- वायु गुणवत्ता निगरानी प्रणाली

- ऑनलाइन सतत उत्सर्जन निगरानी प्रणाली-ओसीईएमएस

- ओस प्वाइंट मॉनिटर्स

- गैस डिटेक्टर

- अपारदर्शिता मॉनिटर

- पोर्टेबल फ़्लू गैस विश्लेषक

- ऑनलाइन एसओएक्स और एनओएक्स गैस विश्लेषक

- मीथेन गैस रिसाव डिटेक्टर

- हाइड्रोजन शुद्धता विश्लेषक

- गैस शुद्धता विश्लेषक

- प्रवाह निगरानी प्रणाली

- निर्माता गैस विश्लेषक

- गैस डिटेक्टर अंशांकन सेवा

- पोर्टेबल गैस मॉनिटर्स

- गैस सेंसर ट्रांसमीटर

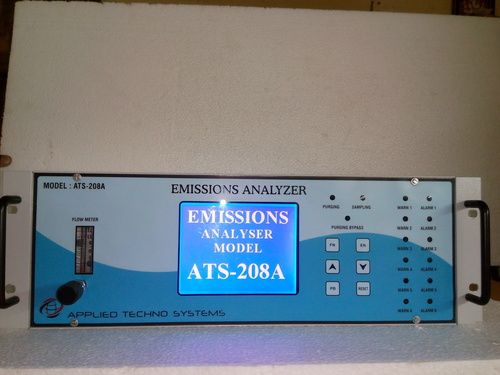

Flue Gas Analyzers

उत्पाद विवरण:

- वोल्टेज वोल्ट (v)

- मटेरियल Aluminium

- तापमान सेल्सियस (oC)

- आयाम (एल* डब्ल्यू* एच) मिलीमीटर (mm)

- उपयोग Industrial

- रंग Grey

- बिजली की आपूर्ति Electric

- अधिक देखने के लिए क्लिक करें

मूल्य और मात्रा

- 1

उत्पाद की विशेषताएं

- किलोग्राम (kg)

- Industrial

- Grey

- Electric

- वोल्ट (v)

- Aluminium

- मिलीमीटर (mm)

- सेल्सियस (oC)

व्यापार सूचना

- ,

- प्रति सप्ताह

- दिन

- , , , , , , , ,

- , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , ,

उत्पाद वर्णन

A flue gas analyzer is a device used to measure the composition of gases emitted from the combustion of fuels in boilers, furnaces, or engines. It is essential in monitoring exhaust gases like carbon monoxide (CO), carbon dioxide (CO2), oxygen (O2), nitrogen oxides (NOx), sulfur dioxide (SO2), and other pollutants to optimize combustion efficiency and ensure compliance with environmental regulations.

The analyzer typically uses a variety of sensors (such as electrochemical, infrared, or chemical sensors) to detect and measure the concentration of gases. Flue gas analyzers are often used in industrial settings, power plants, refineries, and HVAC systems. They help detect issues like incomplete combustion or excessive pollution and aid in maintaining safe operating conditions.

Key Features:

- Multi-gas detection: Measures gases like CO, CO2, O2, NOx, SO2, etc.

- Efficiency monitoring: Helps improve fuel usage and minimize emissions.

- Emission control: Ensures compliance with environmental standards.

- Portable and stationary models: Handheld devices for field use and fixed models for continuous monitoring.

- Data recording: Many models allow for data logging and reporting.

Frequently Asked Questions (FAQs)

What is a flue gas analyzer used for?

A flue gas analyzer is used to measure the concentration of gases in the exhaust emissions of combustion systems, such as furnaces, boilers, and engines. It helps ensure optimal combustion efficiency, lower emissions, and compliance with environmental regulations.

Which gases are measured by a flue gas analyzer?

Commonly measured gases include oxygen (O2), carbon dioxide (CO2), carbon monoxide (CO), nitrogen oxides (NOx), sulfur dioxide (SO2), and sometimes hydrocarbons (HC) and particulate matter.

How does a flue gas analyzer work?

The analyzer uses sensors to detect and measure the concentrations of different gases in the exhaust flue. For example, electrochemical sensors measure O2, while infrared sensors are used for CO and CO2. These readings help operators adjust fuel and air mixtures to optimize combustion.

Why is measuring flue gases important?

Measuring flue gases is critical to ensure the combustion process is running efficiently. It helps reduce fuel consumption, lowers harmful emissions, and ensures compliance with environmental regulations. Monitoring these gases also improves the safety and longevity of combustion systems.

How often should a flue gas analyzer be calibrated?

Calibration should be done at least annually, but more frequent calibration may be needed in high-use or harsh conditions to ensure accurate readings. Some analyzers have auto-calibration features to enhance accuracy.

What industries use flue gas analyzers?

Flue gas analyzers are used across various industries, including power generation, oil and gas, petrochemical, steel manufacturing, HVAC, and automotive industries, where combustion efficiency and emission control are critical.

Can a flue gas analyzer detect gas leaks?

While primarily used to measure exhaust gases, some models can detect gas leaks, especially for flammable or toxic gases like methane (CH4) or carbon monoxide (CO). However, dedicated gas leak detectors are more suitable for that purpose.

What is the difference between a flue gas analyzer and a combustion gas analyzer?

A flue gas analyzer measures the gases in the exhaust or flue of combustion systems to monitor emissions. A combustion gas analyzer is typically used to measure gases inside the combustion chamber itself to optimize the combustion process. Both analyzers share overlapping functions, but flue gas analyzers focus more on post-combustion emissions.

How long do the sensors in a flue gas analyzer last?

Sensor lifespan varies by type and usage but generally ranges from 1 to 3 years. Electrochemical sensors typically need to be replaced more frequently, while infrared sensors last longer.

How can I maintain my flue gas analyzer?

Regular calibration, sensor replacement, and following the manufacturer's maintenance guidelines are essential for ensuring accurate measurements and extending the life of the analyzer. Proper storage and handling of the device also help prevent sensor damage

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese