- Dew Point Meters

- Gas Analysers

- Portable Gas Detector

- Moisture And Dew Point Analyzer

- Dust/Opacity Monitor

- Gas Monitoring Systems

- Gas Leak Detectors

- Gas Transmitters

- VOC Leak Detector

- Air Quality Monitoring System

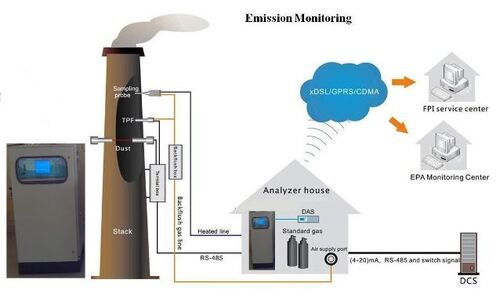

- Online Continuous Emission Monitoring System-OCEMS

- Dew Point Monitors

- Gas Detector

- Opacity Monitor

- Portable Flue Gas Analyzer

- Online SOX & NOX Gas Analyzer

- Methane Gas Leak Detector

- Hydrogen Purity Analyzer

- Gas Purity Analyzer

- Effluent Monitoring Systems

- Producer Gas Analyzer

- Gas Detector Calibration Service

- Portable Gas Monitors

- Gas Sensor Transmitter

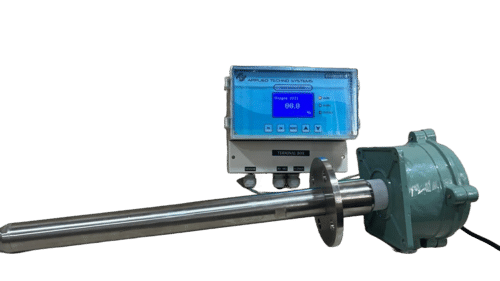

Online Gas stack Gas Analyzer

Price 850000 INR/ Set

Online Gas stack Gas Analyzer Specification

- Port Size

- 1/4

- Color

- Grey

- Power Supply

- 230 V

- Gas Pressure

- 1.5 Bar

- Application

- Stack for analysis of Gas Emission

- Usage

- Industrial

- Product Type

- fixed continuous

- Power

- 230V AC Volt (v)

- Humidity

- 0-95%

- Material

- Aluminum and Metal

- Weight

- 85 Kilograms (kg)

- Temperature

- -5 to 55 Celsius (oC)

- Machine Weight

- 50 Kilograms (kg)

- Control Mode

- Microcontroller

Online Gas stack Gas Analyzer Trade Information

- Minimum Order Quantity

- 1 , , Unit

- Payment Terms

- Cash in Advance (CID), Cheque

- Supply Ability

- 50 Units Per Month

- Delivery Time

- 3-4 Week

- Packaging Details

- wooden

- Main Export Market(s)

- Asia, Africa, Western Europe, North America, Middle East, South America, Eastern Europe, Central America, Australia

- Main Domestic Market

- All India

- Certifications

- TUV India

About Online Gas stack Gas Analyzer

- Online Continuous Emission Monitoring Systems

- Approval : TUV India

- Microcontroller based Online Gas Analyzer for the application of Stack, Boiler and exhaust

- Parameter Measured ; O2, CO, CO2, CH4, Co2, So2, NOx, Cl2, NH3, HF, SPM and Many mores

- Gas Analyzer Model ATS 208A TUV Approved Microcontroller based , easy use can measure 6 parameter simultaneously.

- Gas Analyzer has also the provision of remote calibration facility as per the CPCB guidelines .

Precision and Reliability

This gas analyzer provides real-time, continuous monitoring of stack gas emissions, delivering high-precision results essential for industrial compliance and process control. Its robust construction and advanced microcontroller ensure dependable performance in challenging environments, making it suitable for a range of industries.

Versatile and Easy Integration

Featuring a standard 1/4 port size and operating at 1.5 bar pressure, the analyzer easily integrates with existing systems. Its adaptability across various industrial applications, from manufacturing plants to processing facilities, enhances operational efficiency and compliance with emission regulations.

FAQs of Online Gas stack Gas Analyzer:

Q: How does the Online Gas Stack Gas Analyzer operate in industrial settings?

A: The analyzer utilizes a microcontroller-based control mode to continuously monitor and analyze gas emissions from industrial stacks. It automatically processes sample gases at specified pressure and temperature ranges, ensuring efficiency and regulatory compliance.Q: What types of gases can this analyzer monitor?

A: Designed for stack gas analysis, this analyzer can detect and measure various industrial gases commonly found in emissions, supporting environmental monitoring and process optimization in manufacturing applications.Q: When is it recommended to use this gas analyzer?

A: It is ideal for use whenever continuous monitoring and precise analysis of gas emissions are criticalespecially in industries where compliance with environmental regulations and safety standards is required.Q: Where should the analyzer be installed for optimal performance?

A: Install the analyzer directly on or near stack outlets for continuous sampling. Ensure it is placed within the recommended environmental conditionshumidity of 0-95% and temperature range of -5 to 55Cto maintain accuracy and durability.Q: What is the installation process for this gas analyzer?

A: Connect the device to the stack using its 1/4 size port, secure it in place, and link it to the appropriate 230V AC power supply. The robust aluminum and metal construction ensures straightforward mounting and long-term reliability.Q: How does the analyzer benefit industrial operations?

A: By providing continuous, precise emission data, the analyzer helps industries maintain regulatory compliance, reduce environmental impact, and optimize production processes, ultimately supporting safer and more efficient operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Online Continuous Emission Monitoring System-OCEMS Category

Online SO2 Gas Analyzer

Price 325500.00 INR / Pack

Minimum Order Quantity : 1 Pack

Display Type : Digital

Usage : Emission Monitoring in Industries

Temperature : 5 to +55 Celsius (oC)

Features : High Quality

insitu zirconia based oxygen analyzer

Price 175000 INR / Piece

Minimum Order Quantity : 1 Piece

Display Type : Digital

Usage : Industrial

Temperature : 15 Celsius (oC)

Features : Good Quality

Continuous SO2 Monitoring System

Price 380500.00 INR / Set

Minimum Order Quantity : 1 Set

Display Type : Digital

Usage : Industrial

Temperature : 15 Celsius (oC)

Features : High Quality

Continuous Emission Monitoring System

Price 250000 INR / Number

Minimum Order Quantity : 1 Number

Display Type : Digital

Usage : Industrial

Temperature : 5 to 55 Celsius (oC)

Features : High Quality

Send Inquiry

Send Inquiry